EP - 501

EP-501 is a two part, epoxy thin top coating resin.

It is suitable for places that require wear resistance, corrosion resistance, oil resistance, heavy pressure resistance, seamless and easy to clean.

Uses

- Parking lot, automobile manufacturing, machinery manufacturing, chemical, textile, furniture and other manufacturing plants.

- Storage and assembly halls, maintenance workshops, garages, loading ramps, etc.

Advantages

- Good chemical resistance

- Easy application

- Good mechanical resistance

- Wear resistance

Application Information

Application instructions

1. Substrate quality / Pre-treatment

- The concrete substrate must be sound and of sufficient compressive strength (minimum 211 kgf/cm²) with a minimum pull off strength of 15 kgf/cm².

- Substrate water content is less than 8%.

- All substrates must be clean, dry and free of all contaminants such as dirt, oil, grease, coatings and surface treatments, etc.

2. Mixing

- Prior to mixing, stir EP-501 A mechanically. When all of EP-501 A has been added to EP-501 B, mix continuously for 30 seconds~1 minutes until a uniform mix has been achieved.

3. Application

-

Apply EP-501 by brush or roller.

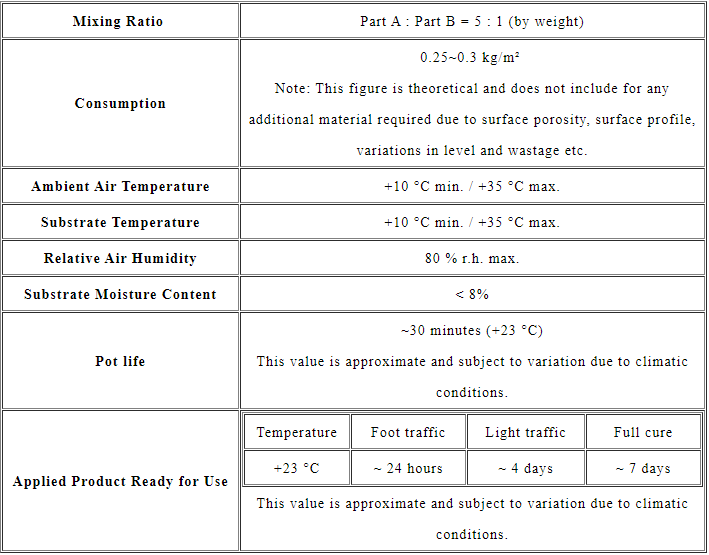

4. Consumption

- 0.25 ~ 0.3 kg / m²

- Note: This figure is theoretical and does not include for any additional material required due to surface porosity, surface profile, variations in level and wastage etc.

5. Maintenance

- To maintain the appearance of the floor after application, EP-501 must be regularly cleaned using rotary brush, mechanical scrubbers, scrubber dryer, high pressure washer, wash and Vacuum techniques using suitable detergents.

6. Cleaning of tools

- Clean all tools and application equipment with thinner immediately after use.

- Hardened and/or cured material can only be removed mechanically.

EP-501

EP-501

EP-501

Packaging / Storage

EP-501 A: 20 kg/plastic pail

EP-501 B: 4 kg/plastic pail

- 6 months in the original, unopened containers at temperatures between +5 °C and +30 °C. Stored in a well ventilated area away from direct sunlight, flame sources and freezing.