Epomota - 6500

Epomota - 6500 is a three- part, water-based epoxy resin mix cement.

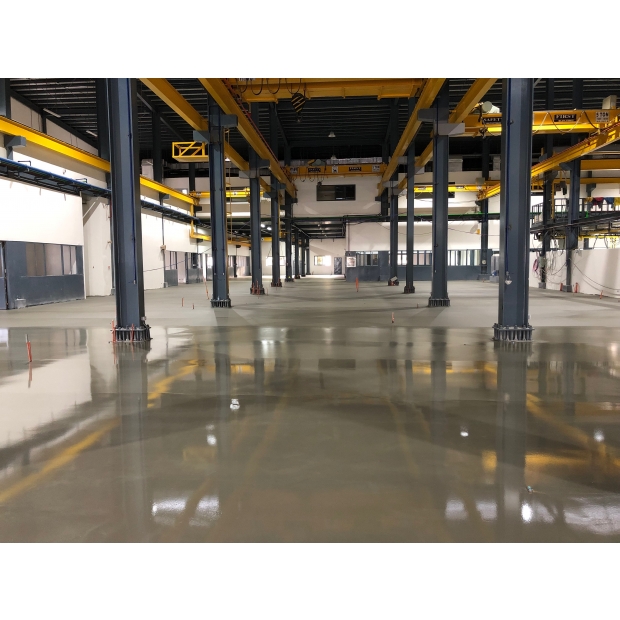

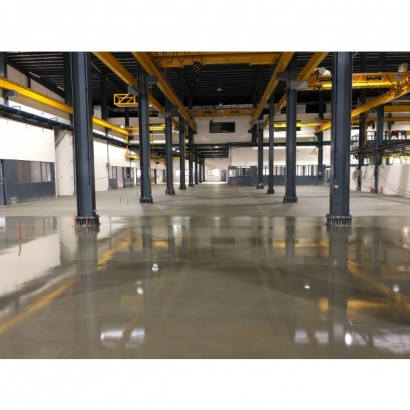

Epomota - 6500 is a high-strength and self-leveling underlayment. It’s convenient and easy to use. It provides a smooth, level surface on which to install a variety of floor coverings.

Epomota - 6500 is a high-strength and self-leveling underlayment. It’s convenient and easy to use. It provides a smooth, level surface on which to install a variety of floor coverings.

Uses

- Epomota - 6500 is well-suited for flattening, smoothing and repairing factory, residential and commercial floors before the installation of final floor coverings.

Advantages

- Self levelling

- Easy application

- Good compressive strength

- Environmentally friendly

- Cures to provide a flat, hard, smooth surface to receive a variety of floor- covering materials.

Application instructions

1. Substrate quality / Pre-treatment

- The compressive strength of the concrete substrate should be at least 3,000 psi at 28 days with a minimum tensile strength of 15 kgf/cm².

- Substrate water content is less than 8%.

- Surface treatments or any friable areas of the subfloor must be mechanically removed.

- All substrate must be dry, stable, sound and free of all contaminants such as grease, oil, paint, wax, dust, curing and sealing compounds that will interfere with the penetration the primer.

2. Mixing

- Epomota - 6500A and Epomota - 6500B mixed at weight ratio of 1:1 .

- Mix with a high-speed drill (> 650 rpm) and an egg beater style mixing paddle to blend for approximately 1~2 minutes, until to minimize entrapped air and uniform mix has been produced.

- Pour 3.7~4 kg of clean, cool potable water into the mixed resin, ensuring strict control of the water content (do not over-water), and stir evenly.

- Add 25 kg Epomota - 6500C to the resin water, while slowly mixing, adding the complete contents of the bag.

- Mix with a high-speed drill (> 650 rpm) and an egg beater style mixing paddle to blend water and powder for approximately 2~3 minutes, until a lump-free and uniform mix has been produced.

- Note: Operating time: 10 ~ 15 minutes (temperature: + 15 ~ + 35 ° C)

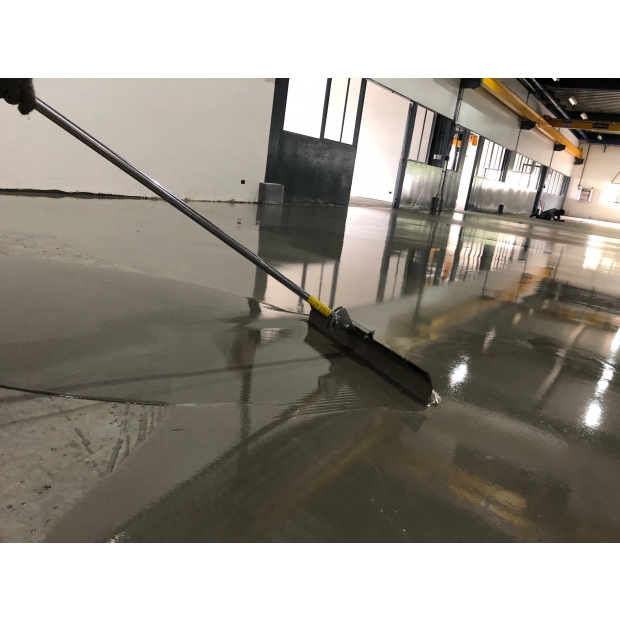

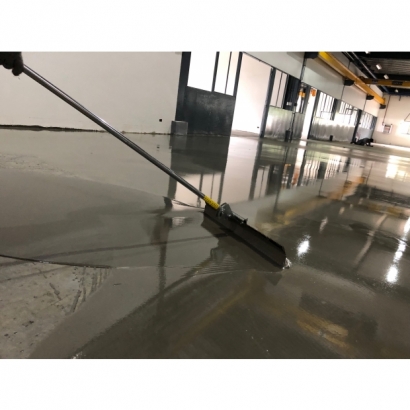

3. Application

- Pour the mix and spread evenly, and control the material thickness by scrape rake.

- Even surfaces by smoothing trowel.

- Roll immediately with a spiked roller to ensure even thickness and achieve defoaming effect.

4. Consumption

- 1.8~2 kg / m² applied as a self-smoothing wearing course.

- Note: This figure is theoretical and does not include for any additional material required due to surface porosity, surface profile, variations in level and wastage etc.

Epomota-6500

Epomota-6500

Epomota-6500

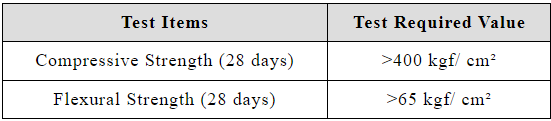

Technical Information

Packaging / Storage

Part A:4 kg/ bucket

Part B:4 kg / bucket

Part C:100 kg/4 paper bag

-

6 months in original sealed container stored in a well ventilated area away from direct sunlight, flame sources and freezing. Relative humidity below 85%, temperature +5°C ~ +35°C.