WEP - 100

WEP-100 was the environmental friendly based composed of epoxy resin and aqueous polyamides, exhibited excellent water proof, chemical resistance and adhesion. It promotes interlayer adhesion with the top through uniform penetration of concrete and mortar surfaces.

Uses

- Dispersion primer for floors

- For priming to the application of floor levelers and fairing coats.

- For priming on absorbent substrate.

- Treating the surface of gypsum, concrete, masonry, tiles, insulation foams, bituminous surfaces, plaster, cementitious renders, screeds and mortars before skimming the surface or applying adhesive.

Advantages

- Adhesion promoter between old substrate with new coat on horizontal and vertical surfaces.

- Fix the residual dusting

- Reduce the water absorption of the substrate.

- Water resistance

- Chemical resistance

- Solvent free, very low emissions.

- Prevents blowholes forming and rapid drying when leveling the substrate.

- Green Building Materials Mark.

Application instructions

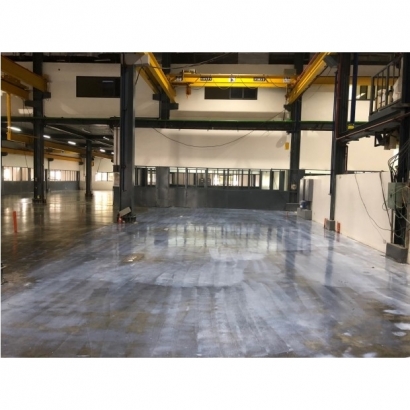

1. Substrate quality / Pre-treatment

- The compressive strength of the concrete substrate should be at least 3,000 psi at 28 days with a minimum tensile strength of 15 kgf/cm².

- Substrate water content is less than 8%, maximum ambient humidity 85%.

- Surface treatments or any friable areas of the subfloor must be mechanically removed.

- All substrates must be dry, stable, sound and free of all contaminants such as grease, oil, paint, wax, dust, curing and sealing compounds that will interfere with the penetration the primer.

2. Mixing

- A(main dosage) and B(hardener) mixed at weight ratio of 1:1.

- Mix with a high-speed drill (> 650 rpm) and an egg beater style mixing paddle to blend for approximately 2~3 minutes, until to minimize entrapped air and uniform mix has been produced.

- Add water of 1-2 times weight of water ,stirred at low speed for 1-2mins till uniform.(dilute ratio will vary depending on the porosity of the substrates)

3. Application

- Cross coating on the construction surface with roller or brush also can apply by machine spray.

- After the first application, wait 4 hours to 1day (+23°C) before applying the second application(If the surface has many pores and the concrete substrate is highly absorbent)

- Note: Operating time: 15-20 minutes (temperature: + 15 ~ + 35 ° C)

4. Consumption

- 0.2 - 0.3 kg / m²

- Note: This figure is theoretical and does not include for any additional material required due to surface porosity, surface profile, variations in level and wastage etc.

WEP-100

WEP-100

WEP-100

Technical Information

Packaging / Storage

WEP-100A:10 kg/bucket

WEP-100B:10 kg/bucket

- Shelf Life:12 months from date of production if stored properly in original, unopened and undamaged sealed packaging

- Store dry at +5~+35 °C Protect from moisture, direct sunlight, flame sources and freezing.