SN - 200

SN-200 is used for waterproofing and chemical protection at both above and below ground level. SN-200 is applied by brush or spray to either the positive or the negative side of the concrete and in the presence of moisture penetrates deeply into the structure. The ensuing chemical reaction fills microcracks, pores and capillaries with an insoluble crystalline formation, which prevents water and water-borne chemicals from entering, even under high hydrostatic pressure.

Uses

- Basement retaining walls

- Parking structures

- Concrete slabs (floor/roof/balcony, etc.)

- Tunnels and subway systems

- Construction joints

- Foundations

- Water retaining structures

- Swimming pools

- Sewage and water treatment plants

- Reservoirs

- Bridges, dams and roads

Advantages

- Easy application

- Integral protection for the entire concrete.

- Permanent protection even if the surface is damaged.

- Protection from any direction.

- Time-Saving.

- Non-toxic.

- Environmental friendly.

Application instructions

1. Substrate quality / Pre-treatment

- The compressive strength of the concrete substrate should be at least 3,000 psi at 28 days with a minimum tensile strength of 15 kgf/cm².

- Surface treatments or any friable areas of the subfloor must be mechanically removed.

- All substrates must be clean and have an open capillary surface.remove laitance,dirt,grease,etc. by means of high pressure water jetting,wet sandblasting or wire brushing.faulty concrete in the form of crack,honeycombing,etc.must fill out with polymer modify mortar,treat with SN-200 surfaces must be carefully pre-watered,the concrete surface must be damp but with no wet sheen on the surface.

2. Mixing

- Pour clean, cool potable water into a suitably sized and clean mixing container, ensuring strict control of the water content (do not over-water).

- Add SN-200 to the water, while slowly mixing, adding the complete contents of the bag.

- Mix with a high-speed drill (> 650 rpm) and an egg beater style mixing paddle to blend water and powder for approximately 2~3 minutes, until a lump-free and uniform mix has been produced.

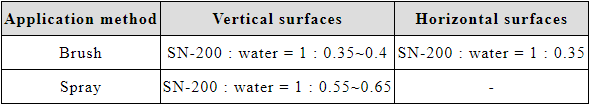

- Mixing ratios:

3. Application

- Cross coating on the construction surface with roller or brush also can apply by machine spray.

- Note:Operating time: 20-30 minutes (temperature: + 15 ~ + 35 ° C)

- Note:If the mixture starts to set, do not add more water; simply re-stir to restore workability.

4. Consumption

- Approx:1.2-1.6 kg/m2 (2 coat)

- Note: This figure is theoretical and does not include for any additional material required due to surface porosity, surface profile, variations in level and wastage etc.

5. Maintenance

- The treated areas should be kept damp for a period of five days and must be protected against direct sun, wind and frost, by covering with polyethylene sheeting, damp burlap or similar.

- If the weather is extremely hot, the number of maintenance days can be increased.

6. Cleaning of tools

- Clean all tools and application equipment with water immediately after use.

- Hardened / cured material can only be removed mechanically.

SN-200

SN-200

SN-200

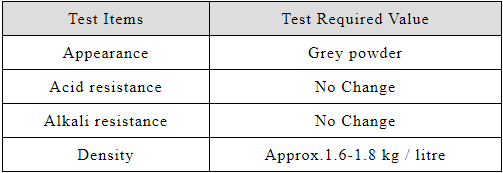

Technical Information

Packaging / Storage

SN-200:25 kg/paper bag

- Shelf Life:12 months from date of production if stored properly in original, unopened and undamaged sealed packaging

- Store dry at +5~+35 °C Protect from moisture, direct sunlight, flame sources and freezing.