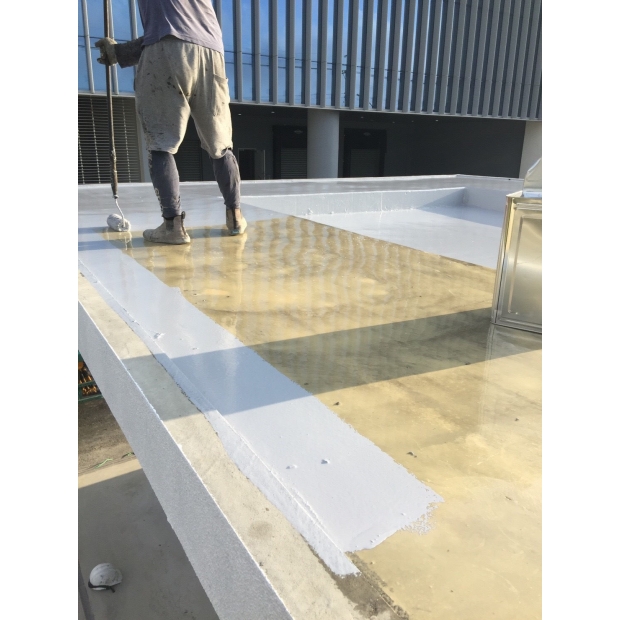

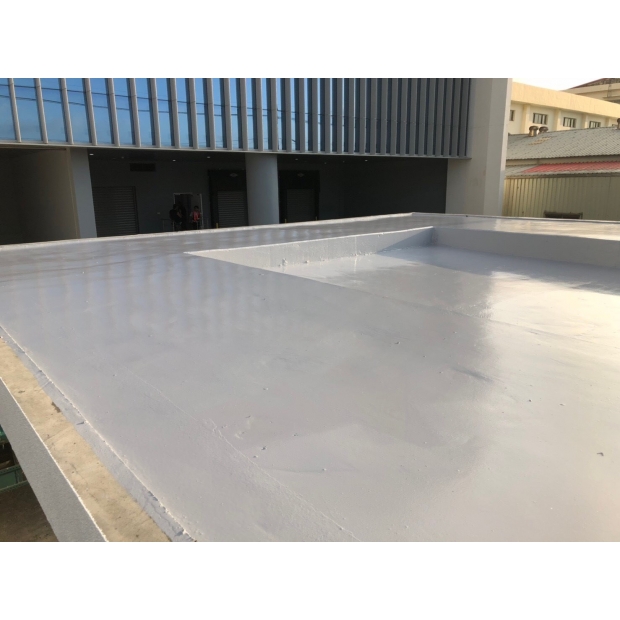

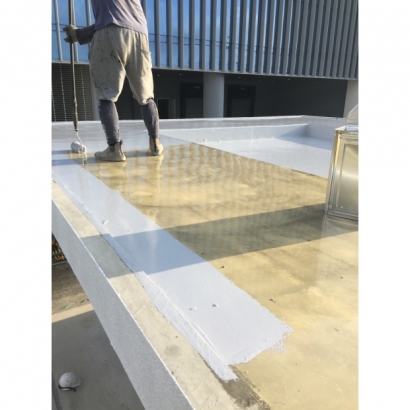

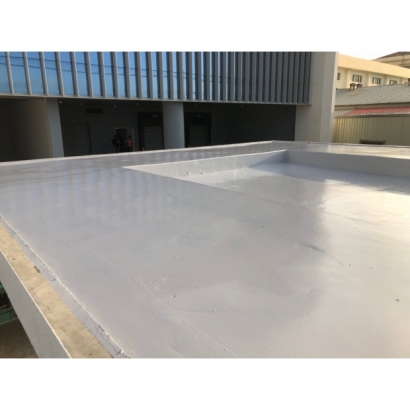

2U - 501

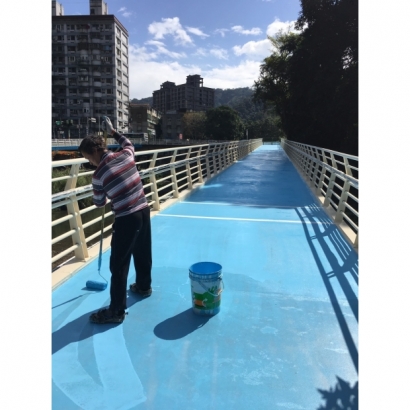

2U-501 is a non-yellowing topcoat. It will not change color or fade due to light exposure after coating. It has excellent weather resistance and UV resistance, especially suitable for use in outdoor environments.

Uses

- Roof, roof parking or multi-dimensional parking, DECK floor

- factory warehouse

- stadium stands

- bridges, roads

Advantages

- Excellent UV resistance

- Excellent weather resistance

- Oil resistant

- Water resistant

- Acid and alkali resistant

- Wear resistant

Application instructions

1. Substrate quality / Pre-treatment

- The concrete substrate must be sound and of sufficient compressive strength (minimum 211 kgf/cm²) with a minimum pull off strength of 15 kgf/cm².

- Substrate water content is less than 8%.

- curing above 28 days to flatten surface fill honeybomb with EPOXY resin and surface pretreatment with ball sandblasting, no sand, dust, grease allowed.

2. Mixing Ratio

- Part A : Part B = 4 : 1 (by weight)

3. Application

- Apply 2U-501 by brush or roller.

4. Consumption

- 0.25-0.3 kg / m2 / mm

- Note: This figure is theoretical and does not include for any additional material required due to surface porosity, surface profile, variations in level and wastage etc.

5. Maintenance

- To maintain the appearance of the floor after application, EP-501 must be regularly cleaned using rotary brush, mechanical scrubbers, scrubber dryer, high pressure washer, wash and Vacuum techniques using suitable detergents.

6. Cleaning of tools

- Clean all tools and application equipment with water immediately after use.

- Hardened / cured material can only be removed mechanically.

2U-501

2U-501

2U-501

Technical Information

.png)

Packaging / Storage

Part A: 20 kg/metal pail

Part B: 5 kg /metal pail

- Shelf Life:6 months from date of production if stored properly in original, unopened and undamaged sealed packaging

- Store dry at +5~+35 °C Protect from moisture, direct sunlight, flame sources and freezing.